De-NOx (SNCR, SCR)

Nitrogen oxides belong to the family of poisonous, highly reactive gases. These gases are formed when fuels are burned at high temperatures. These kinds of gases are released by automobiles and few industrial machines. Nitrogen oxides are generally brownish colored gases, strong oxidizing agent and react easily with volatile organic compounds that make ozone on hot summer days.

Industrial places such as glass manufacturing plants or cement industries require to install equipments/systems for NOx reduction. Commonly used systems are SCNR (Selective Non-Catalytic Reduction) or SCR (Selective Catalytic Reduction).

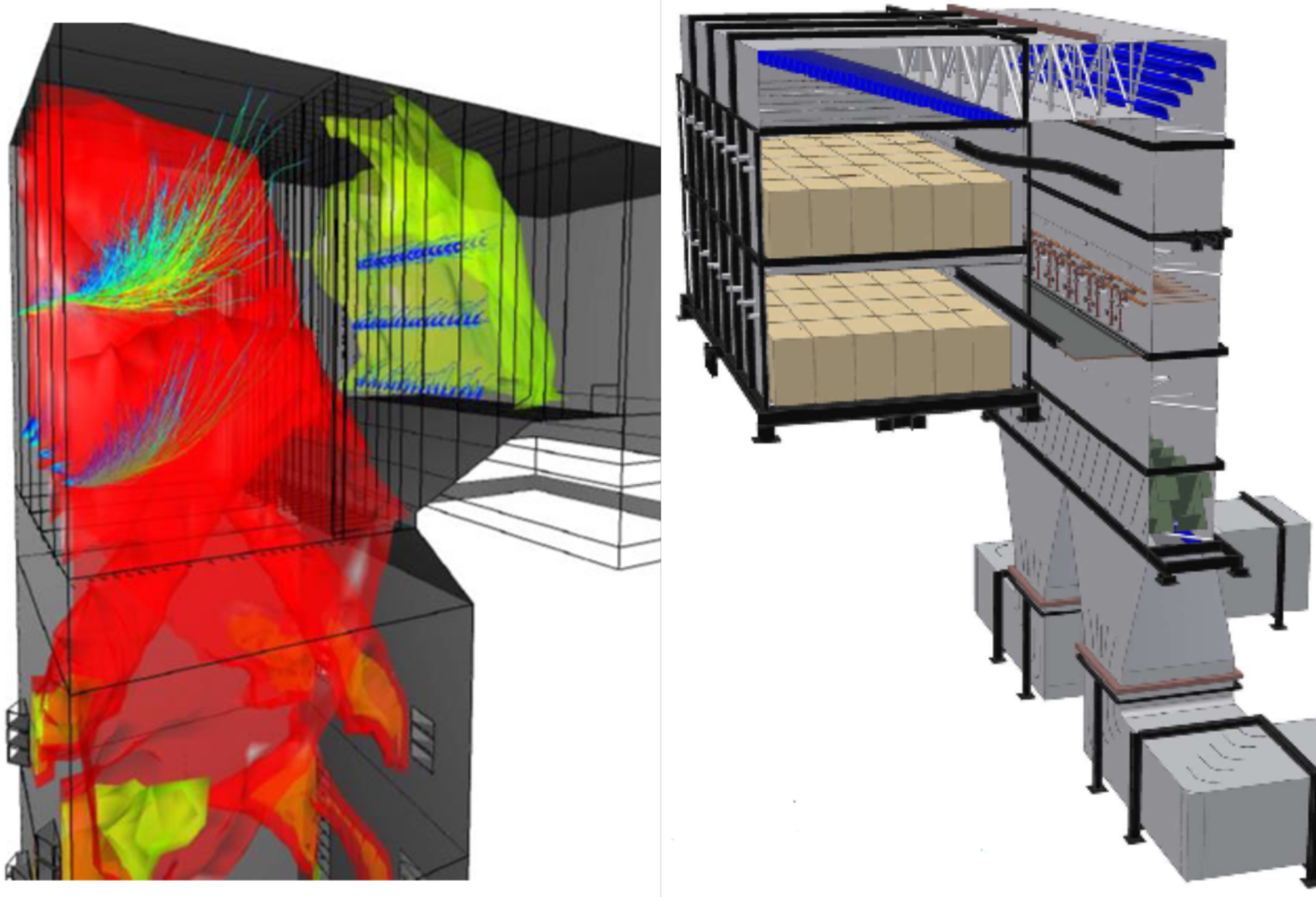

SCNR (Selective Non-Catalytic Reduction):

SCNR (Selective Non-Catalytic Reduction) is a process that involves injection of the reagent directly over the combustion for reducing emissions of nitrogen oxides where temperatures are maintained between 850 and 1050°C. Such processes are majorly used in boilers with conventional fuels, cement industries, etc.

SCR (Selective Catalytic Reduction) :

Selective Catalytic Reduction (SCR) technology is a process where catalyst is used for reduction of emissions of nitrogen oxides. This process can help to achieve upto 95% reduction of NOx.

Benefits of SCR:

- The temperature at the point of injection is pretty lower than that in the SNCR system around 350°C.

- The catalyst used in SCR method favors the reduction of NOx due to the use of selected agent (urea solution) that produces nitrogen and water resulting in restricted side reactions and assuring good results of upto 95% reduction.